|

Applies To |

|

|

|

Product(s): |

WaterGEMS, WaterCAD |

|

|

Version(s): |

CONNECT Edition, V8i |

|

|

Area: |

Modeling |

|

|

Original Author: |

Mark Pachlhofer, Bentley Technical Support Group |

|

Problem

How do you set up an EPS (Extended Period Simulation) scenario for fire flow that would run for a certain amount of time?

Or, how can you compare automated fireflow results to a manual EPS check?

Solution

In some cases you may want to see the impact of the duration of a fire event, such as how long it will take to drain storage tanks. The traditional automated fire flow tool is a steady state run only, so you must manually set up an EPS simulation that uses a pattern to peak the demand at whichever hydrants or junctions you'd like to run the fire flow on.

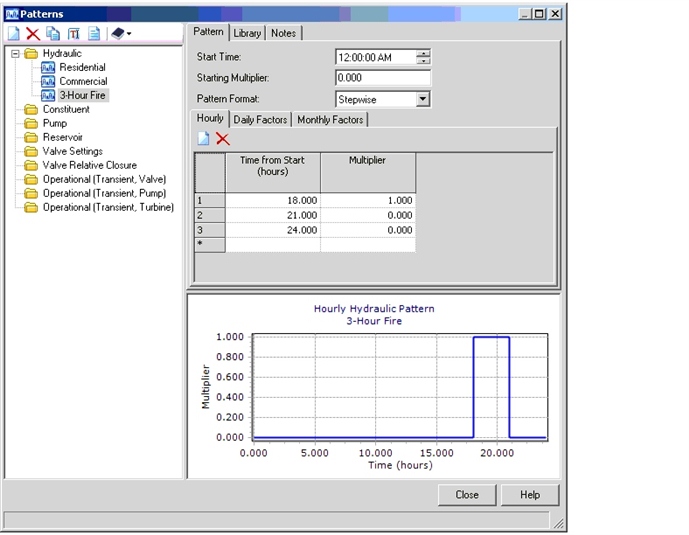

The screenshot below shows how you might set your pattern up of you were running a 3 hour fire flow at 2,000 L/min from hours 18-20 from your simulation start time.

The automated fire flow analysis calculates the water that can be delivered to a node for fire fighting at one point in time (steady state). Therefore, an extended period simulation (EPS) does not apply and cannot be run with this tool.

By setting the calculation option "Is EPS Snapshot" to True, the fire flow analysis will consider the starting date and time and apply the appropriate pattern multipliers for that time. However, this is still a steady-state analysis.

Comparing Automated Fireflow Results to EPS

If you are running an Extended Period Simulation (EPS) with a demand set on a hydrant or junction that is equal to the available fireflow observed from an automated fireflow run, results can be different due to:

- Demand conditions elsewhere in the model: If you have demand patterns, you will need to use an EPS Snapshot with your automated fireflow run, where the time is set to time that you are observing during the EPS run. This will ensure that pattern multipliers are applied to the demands so as to make an equivalent "apples to apples" comparison. Also, ensure that the available fireflow demand that you have added to the node in question is removed in the fireflow scenario that you are comparing to, otherwise it will be counted twice (unless you have selected the option in the firelfow alternative to replace baseline demands). Lastly, your EPS scenario should have a pattern applied to the fireflow demand (see above) to simulate when and for how long the fire will occur, otherwise the demand will be applied during the entire simulation.

- Tank levels: it is important to remember that tank levels can change during an EPS whereas during automated fireflow a snapshot of time is examined, during which the tank level is equal to the initial level that you have set. During an EPS, tanks can fill or drain, impacting results such as pressure at later times during the simulation. This is even more likely to occur in an EPS with a fireflow demand added, as the large demand will tend to cause tanks to drain quickly.

- Element status: similar to tank level, if other elements are changing status during the EPS (such as pump and valve status), you will need to manually change the initial status of those elements to match, in the fireflow scenario. Be sure to use separate Initial Settings alternatives in the two scenarios in question.

Running a steady state fire flow at the peak conditions of an EPS

In some cases, a standard check would be to look at a range of fire flows and the resulting pressures, at the worst-case time during an EPS. For this, you can use the new "EPS Fire Analysis" tool available for the CONNECT Edition:

Fire flow analysis at the time of minimum pressure (EPS Fire Flow Analysis Tool)

See Also

EPS (Extended Period Simulation) Fire Flow Analysis Tool

Understanding Automated Fire Flow Results

WaterGEMS and WaterCAD Automated Fire Flow FAQ