| |

Applies To |

|

|

| |

Product(s): |

HAMMER |

|

| |

Version(s): |

CONNECT Edition, V8i |

|

| |

Area: |

Modeling |

|

| |

Original Author: |

Scott Kampa, Bentley Technical Support Group |

|

Problem

How can the wave speed be entered for pipes?

What does the follow user notification mean? "Wave Speed must be greater than zero."

Solution

For HAMMER to complete the transient calculations, the wave speed of the pipe must be entered. This is also known as the celerity and determines how fast a pressure wave travels in a pipe during transient conditions. There are several options for setting pipe wave speed as outlined below.

Pipe Properties or Flextables

If you double click on the pipe to view the Properties, you will see an item for Wave Speed. If you know the wave speed of the pipe, you can enter it in this space. You can also use the Pipe Flextable to enter or global edit the wave speed property.

Global Calculation Option

Alternatively, you can leave the wave speed as zero in the pipe properties and use the "Pressure Wave Speed" transient calculation option to globally apply a wave speed to all pipes with a zero wave speed. This is found under Analysis > Calculation Options > Transient Calculation Options.

ModelBuilder

If you need to compute the wave speed using a certain formula or method, or if you already have the wave speeds in an external source (for example an Excel spreadsheet), you can use the ModelBuilder tool to import them. The external source will need to have a column with the label or ID of the pipe, which you would use as the Key Field in ModelBuilder.

Wave Speed Calculator

HAMMER also includes a wave speed calculator that will derive the wave speed for each pipe in the model (since different materials will have different wave speeds.)

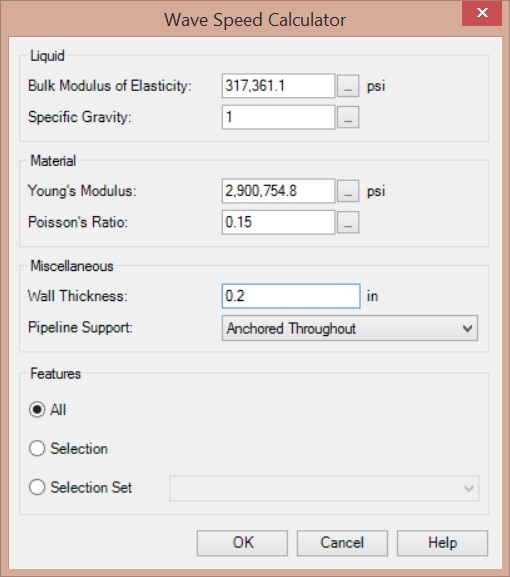

To use the wave speed calculator, go to Tools > Wave Speed Calculator. While you can enter the known values for the different parameters, you can also simply select the liquid type and material from the engineering library. Click the ellipsis ("...") button beside Bulk Modulus of Elasticity and select the liquid. The Bulk Modulus and Specific Gravity will be filled in. Then, click the ellipsis next to Young's Modulus and select the material being used in the model. Once this is done, Young's Modulus and Poisson's Ratio will be filled in. Now enter the wall thickness and choose the pipeline support. Once completed, choose Okay.

Note that this method uses an equation that is generally considered valid for thin-walled pipelines where the diameter divided by the wall thickness is greater than 40. If you are working with a pipe that may not be appropriate for this equation, use one of the other methods above to enter your wave speed. See more here: Equation used in Wave Speed Calculator tool

Note also that when selecting from the material library, not all of the materials included in the default library have their Young's Modulus and Poisson's ratio populated, so you will need to use your judgement to decide what to enter. Consider a sensitivity analysis if unsure: try a range of values and compare transient results to see if it is sensitive. For concrete pipes the strength will depend on the mixture of cement, aggregate, water and other things in the mix and varies over time.

The computed Wave Speeds will be applied to pipes, per the option you select under "Features". You will see the updated wave speed in the pipe properties.

Note that if you have more than one type of material, you can apply the wave speed calculated to a given selection set composed of pipes of the same material. This selection set will need to be created ahead of time.

Wave Speed for Lined Pipes (compound / composite)

The lining of a pipe, or weather it is a compound pipe, will impact the wave speed. See: Transient implications of soil, pipe lining, material and thickness

See Also

Equation used in Wave Speed Calculator tool

Understanding length/wave speed adjustments and their impact on results