| |

Product(s): |

HAMMER |

|

| |

Version(s): |

V8i, CONNECT Edition |

|

| |

Area: |

Modeling |

|

Problem

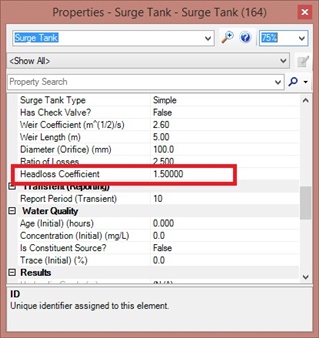

How can you calculate the headloss coefficient for the orifice of a surge tank, or the "Minor Loss Coefficient (Outflow)" of a hydropneumatic tank?

Solution

Generally speaking, the headloss coefficient that is used is up to your engineering judgment. But if you are not sure of the value to use, you can use the standard headloss equation, Hl = K*V2/2g. where the "K" is the headloss coefficient.

It is important to note that this is different than the "orifice coefficient" or "coefficient of discharge". The velocity will be calculated based on the flow during the transient simulation and the orifice diameter that you entered. So, it affects the amount of headloss between the tank and the pipeline.

Another possible approach would be to back-calculate the headloss coefficient either using the orifice equation or a known head drop for a corresponding known flow (through the tank/pipe connection). In some cases, the connection between the tank and the pipeline may contain a check valve with a bypass, so that flow in one direction experiences more head loss than the other. In this case, you would use the "Ratio of Losses" field to account for this difference. (see link further below)

You could also conduct a sensitivity analysis if unsure - try a range of values and see if the transient results of interest have any notable change (sensitivity).

Another option would be to model the headloss outside of the tank element, such as in the pipe connected to the surge tank or as an Orifice Between Pipe element.

If you want to neglect headloss across the tank inlet (assume headloss is zero), you could set the headloss/minor loss coefficient to zero.

See Also

Headloss reporting through a surge tank in HAMMER

Using the Ratio of Losses field for hydropneumatic tanks and surge tanks