| Product(s): |

WaterSight |

| Version(s): |

10.00. |

| Area: |

Documentation |

Overview

Administration page used to import pump information into WaterSight.

It is possible to import pump information through a configuration Excel file (template file available for download in the Digital Twin Setup page) or to manually add a pump and its characteristics. After uploading pump information, it is also possible to edit, delete or copy information, using the available buttons located above the table.

Note: To enable the Copy, Edit, and Remove options, please select a pump first (row in the table). When clicking in a specific pump (table row) the fields available for editing will appear below the pump configuration table.

Curves

There are four optional curves that can be defined for pumps to establish relationships used for graphing and analysis. These are Head Curve, Efficiency Curve, Power Curve, and Speed Efficiency Curve. See the table below for more information on each curve.

Curve definitions must follow these rules:

- Minimum of 5 points (to allow reasonably accurate interpolation)

- No negative values

- No duplicate flow (or speed) values.

If points are entered out of order, they will be sorted by flow (or speed in the case of the Speed Efficiency Curve).

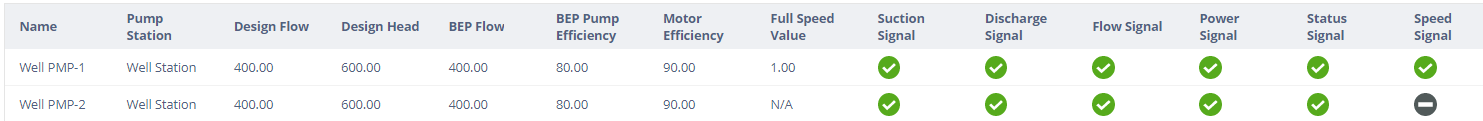

Pump Configuration Table

Note: Minimum required fields are marked with an asterisk.

| Column |

Description |

| Name* |

Required field. Pump display name that will appear in the software. The name should match the label of the pump in the uploaded WaterGEMS model, if applicable.

|

| Pump Station |

The name of the associated Pump Station, if applicable. This name should exactly match the name in the Pump Stations Configuration page. |

| Design Flow |

The flow rate for the design operating point chosen when sizing the pump. The design operating point might not fall directly on the manufacturer flow/head curve. The Design Point will be displayed on graphs for reference.

|

| Design Head |

The pump head for the design operating point chosen when sizing the pump. The design operating point might not fall directly on the manufacturer flow/head curve. The Design Point will be displayed on graphs for reference. |

| BEP Flow |

Best Efficiency Point. The flow rate at which the pump efficiency is highest. The Best Efficiency Point will be displayed on graphs for reference.

|

| BEP Pump Efficiency |

Best Efficiency Point. The maximum efficiency of the pump. The Best Efficiency Point will be displayed on graphs for reference.

|

| Motor Efficiency |

The motor efficiency, which is assumed to be constant across all flows and speeds. Efficiencies of the pump and variable frequency drive are specified separately. |

| Full Speed Value |

Only applicable for pumps with variable frequency drives. The value that the Pump Speed Signal will return when the Variable Frequency Drive is operating at full speed.

If speed is measured in percent, this will be 100. If speed is measured as a decimal between 0 and 1, this will be 1. If speed is measured in frequency, this may be 60 Hz or similar. If speed is measured in revolutions per minute, this may be 1800 RPM or similar.

Values from the Pump Speed Signal will be divided by this Full Speed Value to be converted into a percentage.

|

| Suction Signal |

Indicates whether a signal for the suction conditions of the pump have been specified. The suction signal may either be a pressure signal or a level signal, such as the level of a clearwell that the pump draws from. Suction and discharge signal values will be converted to hydraulic grade and subtracted to determine the pump head at each signal timestep.

If no signal is provided, the suction pressure will be assumed to be 0 for pump head calculations.

|

| Discharge Signal |

Indicates whether a signal for the discharge conditions of the pump have been specified. The discharge signal may either be a pressure signal or a level signal, such as the level of a nearby tank downstream of the tank. Suction and discharge signal values will be converted to hydraulic grade and subtracted to determine the pump head at each signal timestep. In case of a tank level, the reference elevation of the level sensor needs to filled in the sensor administration page so that HGL can be calculated

|

| Flow Signal |

Indicates whether a signal for the flow rate of the pump have been specified.

If no signal is provided, any graphs graphs and calculations that depend on flow rates will not be displayed.

|

| Power Signal |

Indicates whether a signal for the pump power has been specified.

If no signal is provided and a Power Curve is available, the power will be estimated for each timestep based on the flow and head.

|

| Status Signal |

Indicates whether a signal for the pump status has been specified. If available, this will be used to filter analytical results to when the specified pump is active.

|

| Speed Signal |

Indicates whether a signal for the pump speed has been specified. The speed signal may be in units of percentage, or a decimal from 0 to 1, or frequency, or revolutions per minute. The pump speed signal values will be divided by the Full Speed Value to be converted into a percentage. |

| Head Curve |

Indicates whether a pump head curve has been specified. This is a relationship of pump flow to pump head provided by the manufacturer. |

| Efficiency Curve |

Indicates whether a pump efficiency curve has been specified. This is a relationship of pump flow to pump efficiency provided by the manufacturer. Efficiencies of the pump motor and variable frequency drive are specified separately. |

| Power Curve |

Indicates whether a pump power curve has been specified. This is a relationship of pump flow to pump power provided by the manufacturer. This curve represents the power applied to the pump itself, and does not include power consumed by the motor and variable frequency drive. |

| Speed Efficiency Curve |

Only applicable to pumps with variable frequency drives. Indicates whether a speed efficiency curve has been specified. This is a relationship of variable frequency drive speed to drive efficiency. Efficiencies of the pump and motor are specified separately. If no speed efficiency curve is provided, the variable frequency drive will be assumed to be 100% efficient. |

The colored points in the table indicate the following:

|

Signal or curve is configured |

|

Signal or curve is not configured |

|

Signal or curve is not applicable |

Tags (User defined groups)

It is possible to insert tags (or user defined groups) for each pump, by directly filling the Tags column in the Pumps Configuration Template or by directly clicking in a row in the Pumps table, then clicking Edit  and then filling the Tags section below the table.

and then filling the Tags section below the table.

Once tags are defined, those will be available in the Pump Overview page, so that is easier to search and find specific pumps of interest. Below some examples of groups that may be relevant:

- grouping pumps by zones

- grouping pumps by towns

- grouping pumps by critical and non-critical

- etc.

Configuring Pumps

Two different cases may exist:

- SCADA measurements are available for each pump (minimum required is pump flow and head);

- SCADA measurements are available at the pump station level (minimum required is pump station flow and head) and status (on/off) for each pump;

More information here.

See Also

Configuring Pumps

OpenFlows WaterSight TechNotes and FAQ's.